Rebuilding is a crucial aspect of providing our customers with the most value possible. Since machine frames can last for multiple lifecycles, we’ve heavily invested in our full rebuild capabilities rather than constantly turning fleets over. This means we can take any asset that’s seen hours and hours of the harshest environments to new machine-quality entirely in-house.

We understand that just because a machine has run extensively in the field doesn’t mean it’s on its last leg. That’s why Bulk has a dedicated in-house operation focused on restoring heavy equipment back to OEM specs and beyond. This provides our customers the benefits of a new machine for a fraction of the cost.

Focused on restoring heavy-equipment to a better-than-new condition, we build to OEM spec with various upgrades targeted to customer application.

Flexibility to tailor equipment to site-specific needs allows our customers to align machines with their productivity goals.

Our customers run heavy equipment in harsh environments. Consistent exposure to these kinds of extreme conditions can quickly wear down a stock machine. The team has experience with an extensive amount of equipment applications. This means we’re able to apply our background to help creatively design a solution that will enable the asset to stand up to these harsh environments, minimizing downtime and increasing the life of the equipment.

An SMA package can be inclusive of many of the different modifications we perform. Click through to check out some examples.

Protective fire sleeve wrapping and braided stainless-steel coverings on hydraulic hoses, grease lines, and electrical wiring is used for protection from radiant heat. This prevents premature wear, failure and ignition source for compartment and localized fires.

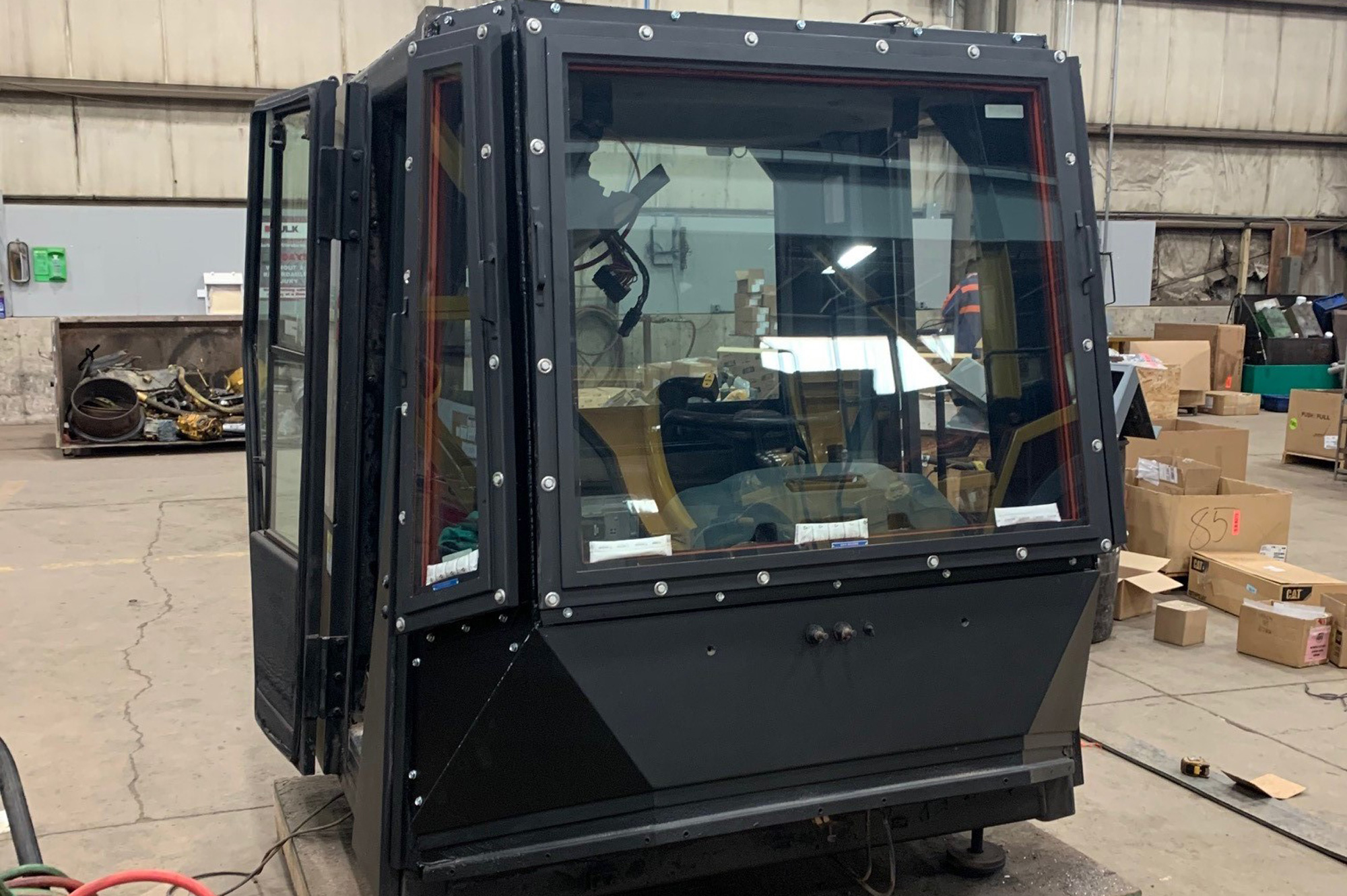

Protective blast-resistant cab windows combine heat-reflective and high-impact qualities to form a protective, blast-resistant glass. This glass increases safety on the front and side windows of machines, helping to safeguard operators digging and loading in slag pits and various furnace areas of steel mills and foundries.

Transmission override allows a machine that’s become disabled in a pit or underneath the furnace to be towed to safety by disengaging the gears in the transmission and shifting to the neutral position.

Fire suppression system is a fast-acting, liquid-based system that detects, extinguishes and prevents reflash. When handling molten slag, the possibilities of fire hazards are extensive. This system is in place to help save the operator’s life in the most dire situations.

Tire chains are used to safeguard tires subject to heavy abrasion and damage when handling molten slag. Specifically-developed and specially-hardened forged wear links ensure optimal tire protection, even during use on these hot and burning surfaces.

High-efficiency, application-specific buckets are built with special materials and reinforced in specific areas that allow the asset to dig and haul molten slag effectively. This extends the life of the buckets and protects the machine as a whole.

Pedestrian detection systems help combat ever-increasing blind spots on machines and blind corners where an operator is unable to see around. When properly installed, based on potential hazards, these systems can provide the operator the split-second notification needed to prevent an incident.

An SMA package can be inclusive of many of the different modifications we perform.

Click through to check out some examples.

Protective fire sleeve wrapping and braided stainless-steel coverings on hydraulic hoses, grease lines, and electrical wiring is used for protection from radiant heat. This prevents premature wear, failure and ignition source for compartment and localized fires.

Protective blast-resistant cab windows combine heat-reflective and high-impact qualities to form a protective, blast-resistant glass. This glass increases safety on the front and side windows of machines, helping to safeguard operators digging and loading in slag pits and various furnace areas of steel mills and foundries.

Transmission override allows a machine that’s become disabled in a pit or underneath the furnace to be towed to safety by disengaging the gears in the transmission and shifting to the neutral position.

Fire suppression system is a fast-acting, liquid-based system that detects, extinguishes and prevents reflash. When handling molten slag, the possibilities of fire hazards are extensive. This system is in place to help save the operator’s life in the most dire situations.

Tire chains are used to safeguard tires subject to heavy abrasion and damage when handling molten slag. Specifically-developed and specially-hardened forged wear links ensure optimal tire protection, even during use on these hot and burning surfaces.

High-efficiency, application-specific buckets are built with special materials and reinforced in specific areas that allow the asset to dig and haul molten slag effectively. This extends the life of the buckets and protects the machine as a whole.

Pedestrian detection systems help combat ever-increasing blind spots on machines and blind corners where an operator is unable to see around. When properly installed, based on potential hazards, these systems can provide the operator the split-second notification needed to prevent an incident.

On arrival, the machine is thoroughly cleaned, inspected, and the team puts together a scope of work based on the condition and needs of the machine.

Before components are reinstalled, the frame is sand-blasted and painted to ensure any imperfections are addressed.

Hydraulic, grease, and electrical lines are replaced to OEM specifications as the asset is built from the ground up.

Counterweights, battery box and other sections of the machine are removed, inspected, and rebuilt if necessary. They’re then sandblasted and painted.

Sandblasted and prepped for paint.

Freshly painted and ready to take the next steps towards heading back to work.

Steel Mill Application (SMA) Front-End Loaders have the base of a tried and tested design with a reinforced frame, cab, and components in order to operate and handle molten steel and blast furnace slag. Designed to protect the operator and reduce the risks when handling molten slag, the front-end loader cab is fitted with impact- and heat-resistant glass. There is also a closed HVAC system to prevent the introduction of gases created when handling the molten slag.

The Straddle Carrier increases productivity for the customer by eliminating the use of flatcars to transport slabs throughout the mill. This asset decreases the number of times the slabs are handled by providing the ability to drive directly over top of the slabs, picking them up, and transporting them directly to the location of the customer’s needs. These machines can also pick and sort through slab piles, selecting specific slabs for their orders, and achieving just in time delivery.

The Pot Carrier is constructed to lift and carry a slag pot designed to the specific capacity of the steel maker’s furnace. It also provides the operator with additional safety features in an effort to further reduce the hazards and to allow for ease of handling and transporting the slag pot to an engineered dumping station.

The prime mover, or tractor, utilizes a scraper design and then updates the operator’s cab with the ability to face in the direction of operation. This improves visibility and increases productivity.

With a modified or purpose-built spreader replacing the container spreader, we hang magnets for slab handling and C-hooks or coil tongs for coil movements. When handling hot slabs, purpose-built slab tongs can withstand temperatures up to 1,100 degrees F are attached. Typical lifting capacity under the lifting device can range from 35 to 50 tons depending on attachment weight and configuration. However, there are manufacturers that are now building Reach Stackers with significantly more lifting capacity. As capacity goes up, maneuverability due to increased wheelbase goes down.

The first Continuous Transport System Bulk supplied to a customer was in 1999. This replaced multiple heavy-duty tractors and trailers along with the labor support required to operate the trucks. Not only were we able to save our customer significant expense by moving from multiple trucks, trailers and drivers to one single machine with one operator, but we were also able to decrease the carbon footprint by burning significantly less fuel while accomplishing the same or more productivity.