It’s true that the Bulk family business bloodline goes back over 80 years and includes experience in both operating and maintaining heavy equipment. But the undercurrent that has been consistent throughout all those years, and which Bulk is built on, is the #yagottawanna way.

Leonard Brown, the man who planted the seed for what years later would become Bulk Equipment Corp., found inspiration in the saying “Ya Gotta Wanna.” Essentially, it means that nothing in business goes right all the time. You take the good with the bad and you make sure that the one thing that stays consistent throughout is hard work and taking pride in your craft.

You’ll find that the #yagottawanna mindset is intrinsic to our core values. To find success, as a business and as an individual, you have to want to do anything necessary to get the job done. These are the values we’re committed to hanging our hard hats on each and every day.

We’re only as good as our last job. We own our mistakes and are willing to do whatever it takes to get the job done right.

The work we do is challenging and essential. When times get hard, we dig deep and remember why we’re here. Our success and the success of our clients relies on us and our willingness to work hard, no matter the circumstances.

Our people are our family. We have a greater responsibility to take care of and provide for those closest to us, and we take that very seriously. We show up for them, respect them, and are always willing to lend a hand.

We actively seek out ways to provide value. The only way we guarantee our work is by becoming as essential to our customers as they are to society.

Solving problems is what we do. We’re not satisfied just doing things the way they were done in the past. We continually seek out new ways of thinking to push ourselves and our industry forward.

Initially safety costs time and money, but no product or service is worth its value if the safety or wellbeing of people is jeopardized in the process. Making sure our Bulk family and customers get home safely every day is a top priority and investing to make that happen is well worth it. This commitment to safety is part of our culture, and in the long run creates more efficient job sites and services.

Where did Bulk come from?

Today, Bulk Equipment Corp. stands as a premier heavy equipment rental and service provider, however our success is not ours alone. We wouldn’t be where we’re at today without the years of knowledge and lessons those who came before us passed on.

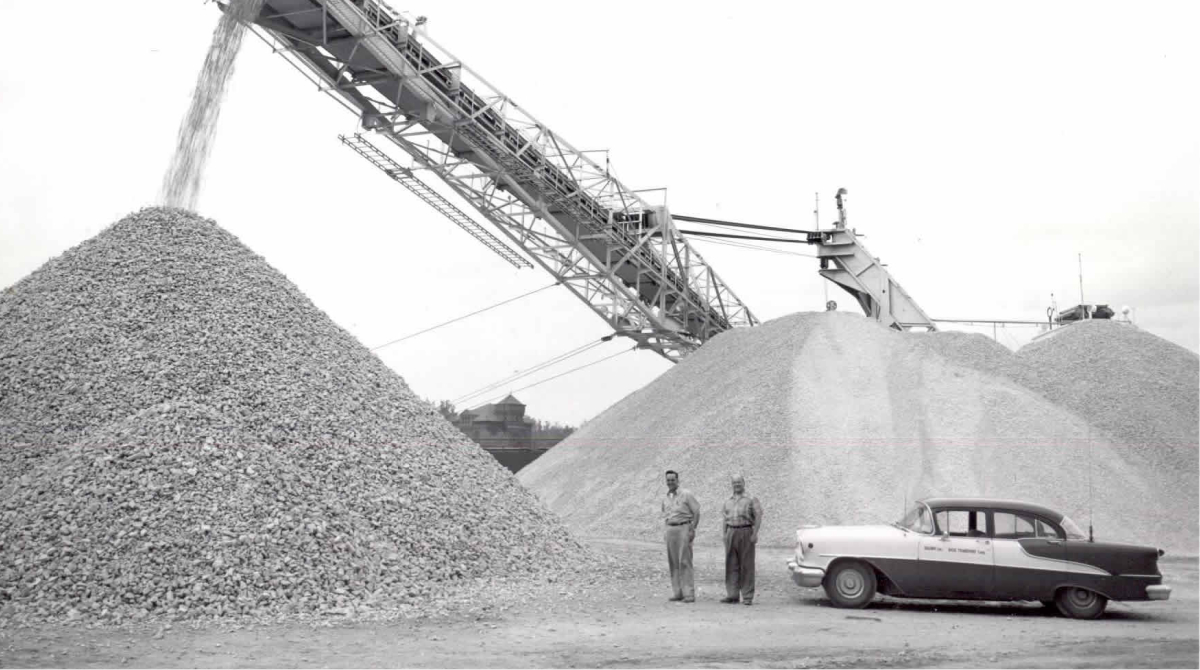

It all started with Clarence “Pappy” Brown delivering sand and gravel to jobsites loading this truck by hand with a shovel. In those days, Pappy would take material directly from the beach on Lake Michigan.

Located at the bottom tip of Lake Michigan, the business was positioned well to handle material transported by barge and ship across the great lakes.

Steel Mill Application (SMA) Front-End Loaders have the base of a tried and tested design with a reinforced frame, cab, and components in order to operate and handle molten steel and blast furnace slag. Designed to protect the operator and reduce the risks when handling molten slag, the front-end loader cab is fitted with impact- and heat-resistant glass. There is also a closed HVAC system to prevent the introduction of gases created when handling the molten slag.

The Straddle Carrier increases productivity for the customer by eliminating the use of flatcars to transport slabs throughout the mill. This asset decreases the number of times the slabs are handled by providing the ability to drive directly over top of the slabs, picking them up, and transporting them directly to the location of the customer’s needs. These machines can also pick and sort through slab piles, selecting specific slabs for their orders, and achieving just in time delivery.

The Pot Carrier is constructed to lift and carry a slag pot designed to the specific capacity of the steel maker’s furnace. It also provides the operator with additional safety features in an effort to further reduce the hazards and to allow for ease of handling and transporting the slag pot to an engineered dumping station.

The prime mover, or tractor, utilizes a scraper design and then updates the operator’s cab with the ability to face in the direction of operation. This improves visibility and increases productivity.

With a modified or purpose-built spreader replacing the container spreader, we hang magnets for slab handling and C-hooks or coil tongs for coil movements. When handling hot slabs, purpose-built slab tongs can withstand temperatures up to 1,100 degrees F are attached. Typical lifting capacity under the lifting device can range from 35 to 50 tons depending on attachment weight and configuration. However, there are manufacturers that are now building Reach Stackers with significantly more lifting capacity. As capacity goes up, maneuverability due to increased wheelbase goes down.

The first Continuous Transport System Bulk supplied to a customer was in 1999. This replaced multiple heavy-duty tractors and trailers along with the labor support required to operate the trucks. Not only were we able to save our customer significant expense by moving from multiple trucks, trailers and drivers to one single machine with one operator, but we were also able to decrease the carbon footprint by burning significantly less fuel while accomplishing the same or more productivity.